Static and fatigue tests of bogie frames and their components

Our testing laboratory performs dozens of certification tests of this type every year. These tests carried out by our laboratory attract great interest of customers from all over the world. We guarantee our unique know-how, technical equipment and everything necessary for good-quality and safe execution of tests.

What is tested

- Railway bogie frames according to ČSN EN 13749

- Bearing chambers based on ČSN EN 13749

- Brake discrepancies according to UIC 833

- Other rolling stock components according to European standards, UIC regulations or created test programs

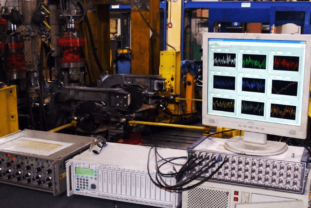

Test bench basic parameters

- Hydraulic actuators in the power range of 20 - 630 kN and the piston rod working stroke of 50-250 mm

- Tensometric measurements of surface tension of up to 140 channels

- 2 test benches for 2 bogie frames to be tested at the same time

- Measurement of reaction forces in all load axes

Options and advantages

- Computer managed and controlled system equipped by TESTControl software

- Application of variable types of static and dynamic loads

- Possibility of continuous course of long-term fatigue and dynamic tests with automatic control of safety limits

Reference projects

- CRRC ZELC Verkehrstechnik: Tests of trailer and traction bogie frame for Double Deck

- Škoda Transportation: Tests of bogie frames for tram 26T, bogie frame cross for NIM Express

- Tatravagonka: Static and fatigue tests of bogie frames of type Y25 and three-axle bogie frame BA715

- European project INNOWAG: Static and fatigue tests of bogie frame made of high-strength steel

- MAPNA Locomotive Engineering & Manufacturing Company: Static and fatigue tests of bogie frame MP24